Pre Engineered Buildings

Basic Building Parameters

The basic parameters that define a pre-engineered building are: Building width, Building length, Building height, Roof slope, End bay length, Interior bay length and Design loads.

If you want a building that has cost saving, fast erection, perfect quality control, high durability, Pre-engineered Buildings (PEBs) are the best choice.

As the latest trend in building construction, PEBs are increasingly confirmed their outstanding advantages in industrial and commercial projects such as factory, warehouse, cold storage, showroom, office, supermarket, school, stadium, logistics center, shopping mall, etc…

What are pre-engineered steel buildings?

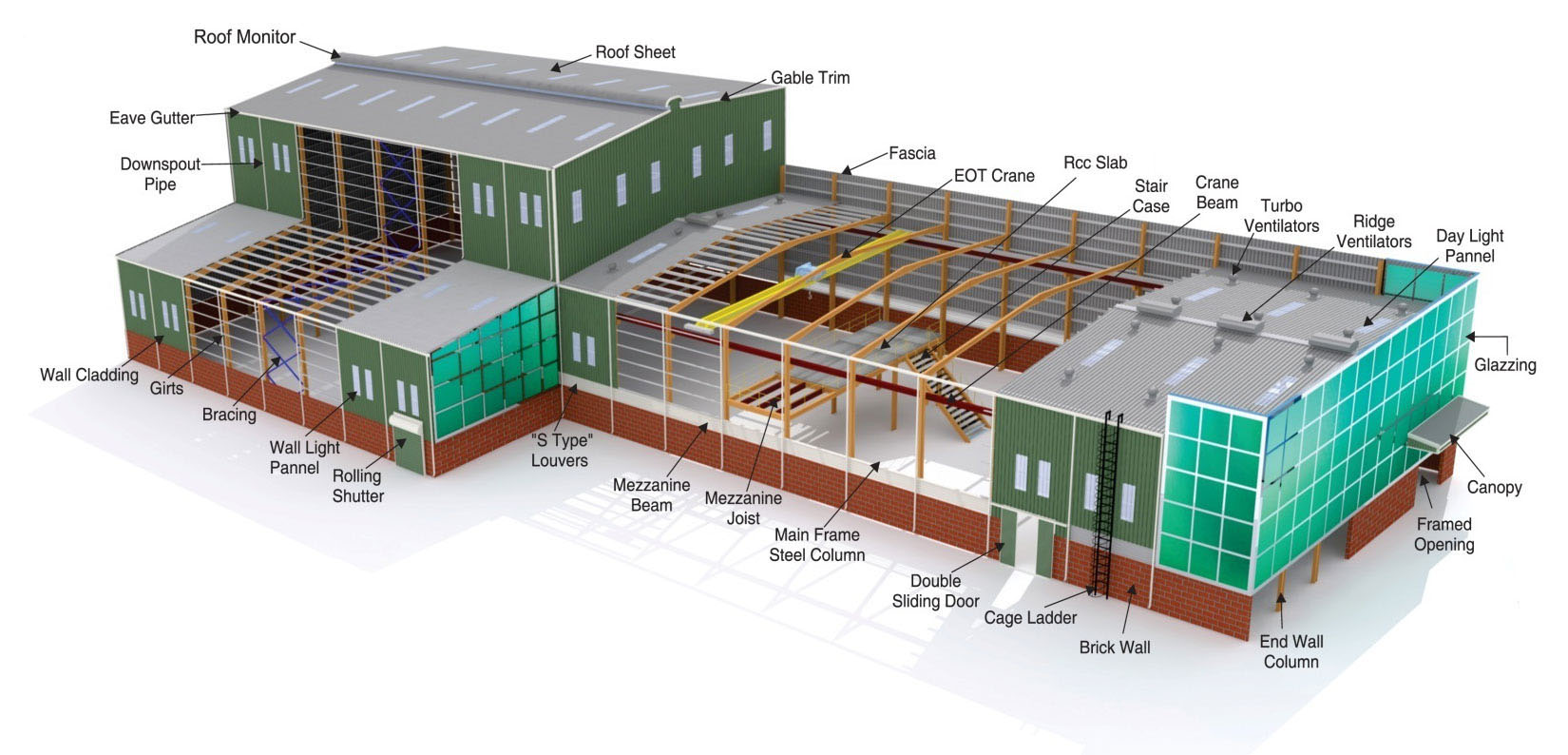

Pre-engineered building are built over three members connected to each other:

The entire primary members and secondary members are designed and fully fabricated including cut-to-length, punching, drilling, welding and preforming in the factory before shipped to the site for erection.

At the site, all components are assembled and jointed via nut & bolt connections; thereby reducing the costs and assembly times.

These buildings can be provided with different structural and non-structural additions such as wall lights, turbo vents, roof monitors, ridge ventilators, doors & windows, trusses, mezzanine floors, canopies, crane systems, insulation…, based on the customer’s requirements.