INTRODUCTION

Daylight Solutions

Daylighting is the controlled admission of natural light, direct sunlight, and diffused-skylight into a building to reduce electric lighting and saving energy. By providing a direct link to the dynamic and perpetually evolving patterns of outdoor illumination, daylighting helps create a visually stimulating and productive environment for building occupants, while reducing as much as one-third of total building energy costs.

Implementing daylighting on a project goes beyond simply listing the components to be gathered and installed. Daylighting requires an integrated design approach to be successful, because it can involve decisions about the building form, siting, climate, building components (such as windows and skylights), lighting controls, and lighting design criteria.

The science of daylighting design is not just how to provide enough daylight to an occupied space, but how to do so without any undesirable side effects. Beyond adding windows or skylights to a space, it involves carefully balancing heat gain and loss, glare control, and variations in daylight availability.

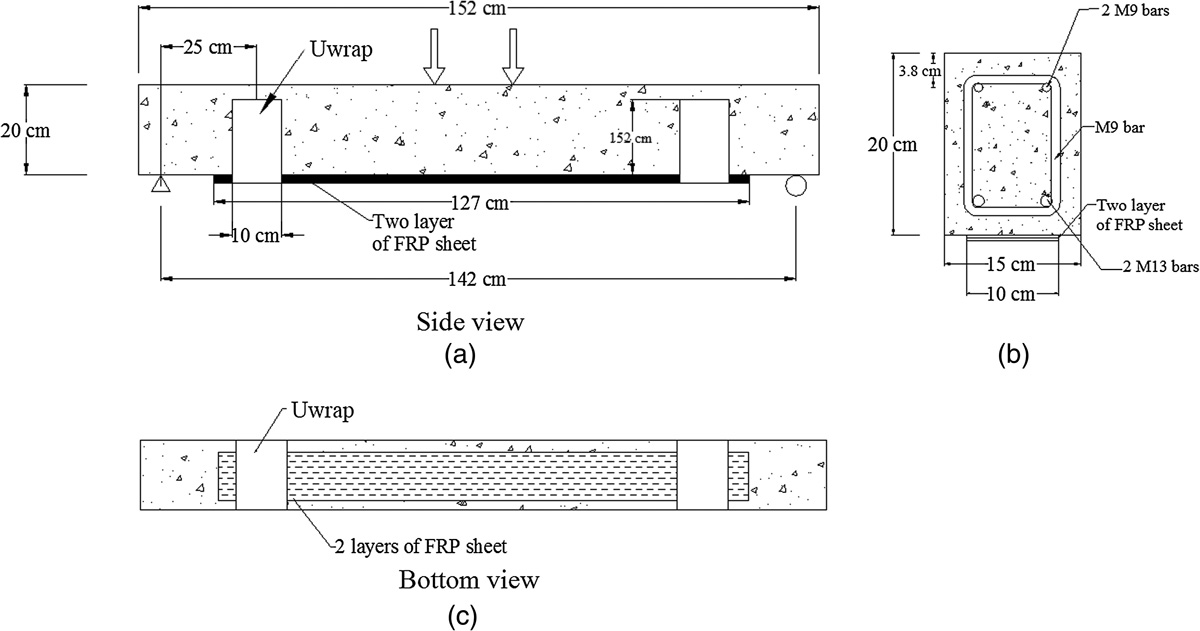

Fibre-Reinforced Plastic (FRP) Sheets

Fibre-reinforced plastic (FRP) (also called fiber-reinforced polymer, or fiber-reinforced plastic) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon fiber reinforced polymer), aramid, or basalt.

The use of FRP in engineering applications enables engineers to obtain significant achievements in the functionality, safety and economy of construction because of their mechanical properties.

Fiberglass reinforced panels, or FRP, are thin, flexible plastic panels made of strong polyester resin reinforced with fiberglass. They are used on walls and ceilings and can be installed directly over drywall, wood, concrete block, and many other solid surfaces.

Polycarbonate sheets

In the plastics industry, polycarbonate sheet is one of the most versatile materials on the market.

Polycarbonate is a thermoplastic that comes in a transparent sheet. It is incredibly tough and absorbs minimal moisture, making it resistant to impact damage as well as water damage. It's also flame-retardant and chemical resistant.

Polycarbonate sheet is as clear as glass and hundreds of times stronger. It's also many times stronger than acrylic sheet - offering a margin of safety that no other clear glazing material can beat. With its inherent design flexibility, polycarbonate can be cut or cold-formed on site during installation without the pre-forming and fabrication associated with glass or acrylic. It is lightweight and requires less structural support compared to all-glass systems, saving additional time and labor costs. Of course, lexan has durability and energy efficiency that quickly adds up to long-term cost savings, too.

Solid/Compact Polycarbonate Sheets

Solid/ Compact Polycarbonate sheets are available in clear and tinted variants. These sheets are generally chosen for applications where vision through the glazing medium is necessary. These sheets are available in a range of thicknesses from 1.3mm to 8mm.

Solid/ Compact Polycarbonate sheets are made from high quality raw materials which offer maximum levels of glazing performance and thus can be used in places where transparency along with tailor made light transmission is of vital importance.

It is lighter than glass but has almost all other properties of glass. It is used in industrial and commercial roofing, defence, decorating interior, skylights, sign boards also as a replacement of glass in some businesses.

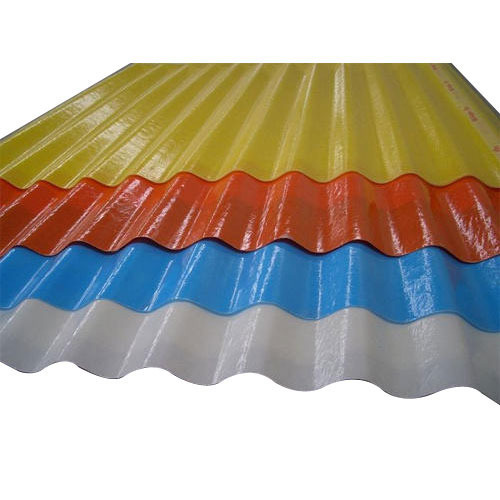

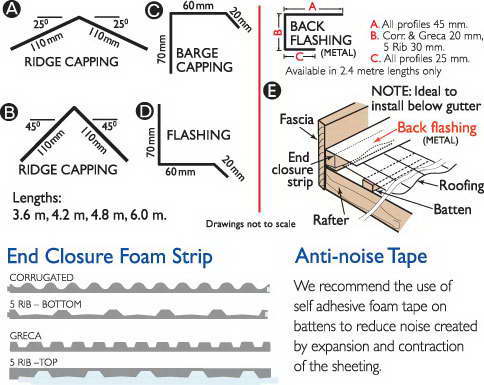

Corrugated Polycarbonate Sheets

Corrugated Polycarbonate sheets are made from high grade polycarbonate resin to deliver outstanding durability and improved lifespans compared to other plastic corrugated sheets.

Particularly Corrugated Polycarbonate Sheets is meant for lighting purpose and is used in Industrial, commercial and domestic areas.

Corrugated polycarbonate sheets feature corrugated surface and self-supporting structure. Self-supporting structure requires less glazing bars decreasing total load of the greenhouse and save installation cost significantly. In contrast to flat polycarbonate sheet such as twin-wall or solid sheets, corrugated sheet can control and adjust the light transmission by changing the direction of the light, allowing for more sunlight for the plants in the morning and evening.

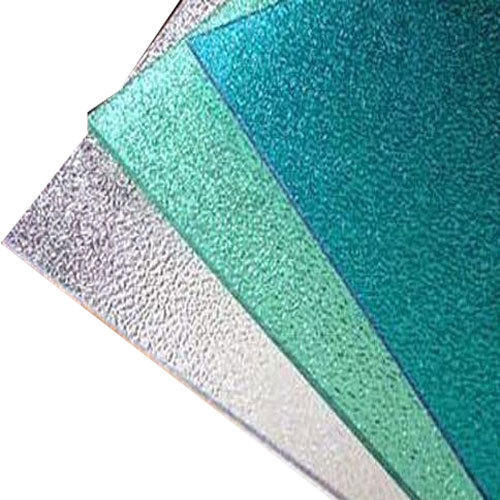

Embossed Polycarbonate Sheets

Embossed Polycarbonate Sheets have several features with high impact resistance, light weight, can be easy cold bend processed and hot molding. Hence, it can be widely used in construction and decorations.

Our wide range of high quality polycarbonate embossed rolls and sheets can be used in various ways and for various applications such as for veranda glazing, safety or vandalized areas indoor/outdoor signs or instrument panels. They are exceptional impact strength and virtually unbreakable. Further, they are UV resistance, self-extinguishable and light transmittance.

Such rolls and sheets come with tiny embossed patterns on one side. Such design not just enhances the look of the polycarbonate rolls and sheets but also enhances its firmness and anti-static function. Besides, they add special effect to the sheet.

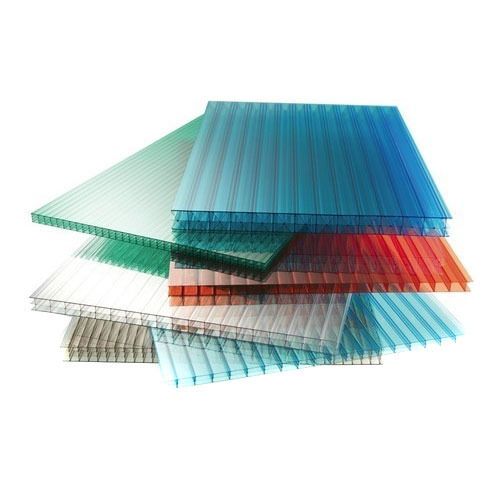

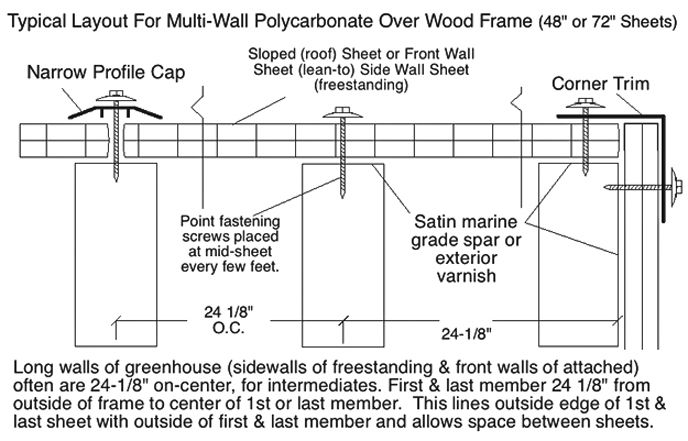

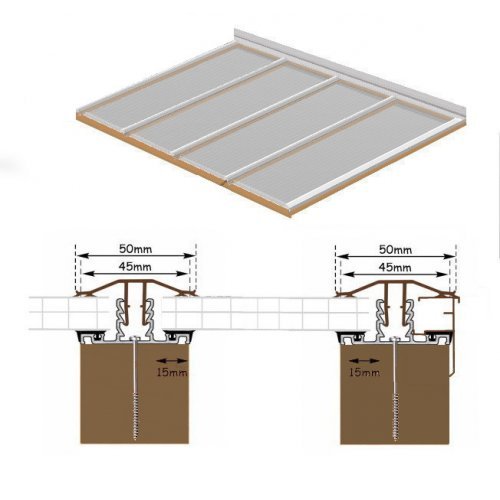

Multi-wall Polycarbonate sheets

Unlike other glazing materials, multi-wall polycarbonate sheet is virtually unbreakable and provides as much as 60% more thermal insulation than glass. Its light weight, durability, strength and ease of installation make it the ideal glazing material, especially for outdoor applications

Structured polycarbonate sheet is the most versatile structured thermoplastic available today. A co-extruded protective layer guarantees the highest stability against the harsh effects of the sun's rays and the multi-walled design gives a stable weathering surface.

The Multiwall sheets provide a wide variety of thicknesses and colors providing up to 82% visible

light transmission. The Multiwall sheets are essentially opaque at all wavelengths below 385 nanometers

limiting the damaging effects of UV light. They have a clear co-extruded outer surface which provides

high stability against the effects of UV radiation and gives excellent durability to outdoor weathering.

This unique protection insures long term optimal quality under intensive UV exposure.